Exterior Canopy, Royal Mail

The historic exterior canopy of the Royal Mail sorting office in Saffron Walden suffered extensive damage when a lorry struck the canopy. Both the canopy structure and one of the large, carved brackets were damaged beyond repair.

With only one of the listed matching brackets left intact, creating a replacement bracket posed a serious problem: With the two identical brackets both fully visible from all angles, any differences in the newly produced bracket and the surviving original would be instantly noticeable.

Refinery’s digitally led process offered a the perfect solution to meet the needs of this repair and we were able to create a replacement bracket that precisely matched the original. With the bracket in place in the restored canopy, no difference can be seen between old and new.

The original canopy and bracket showing the collision damage.

Digital 3D scan data gathered from the remaining bracket.

3D digital model made from scan data of the surviving bracket.

Our process began with the on-site digital 3D capture of the surviving bracket, which was then developed into a production ready 3D digital model of the bracket. This digital counterpart was first used to create drawings and diagrams to facilitate the installation of the bracket and the creation of an internal steel frame.

It was then used to drive the CNC cutting of a large block of Douglas Fur, reducing the timber down to the basic ’near-form’ of the ornate bracket.

With the digital phase of the work complete, the new bracket was taken to its final form by hand carving, leaving crisply defined details and a rich visual language of traditional craftsmanship, making an exact match to the existing bracket in form and authenticity.

3D visuals of the new canopy and bracket to inform installation of steel frame, bracket and canopy.

CNC cutting of the replacement bracket

Finished, hand carved bracket, fitted in place.

Refinery's use of both digital production and traditional process provided a practical and achievable route to making an identical bracket where the limitations of purely traditional methods would have threatened the viability of the repair.

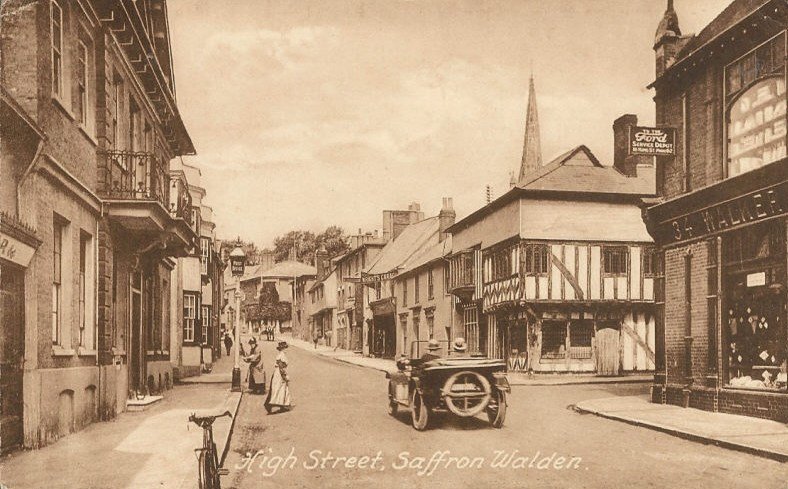

With the canopy now fully restored, it returns an iconic piece of this ancient town’s high street to its original condition when it so easily could have been lost.